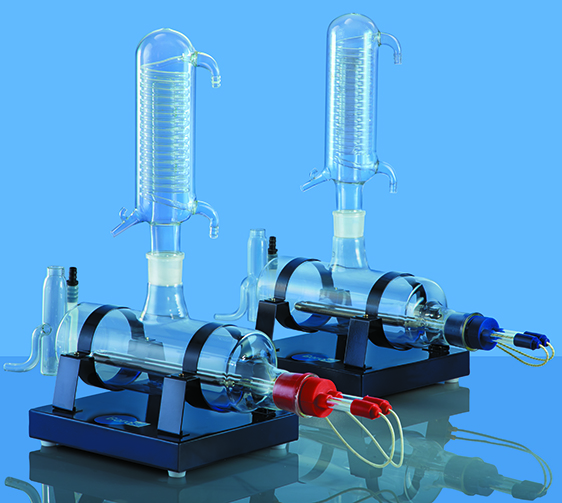

Distillation Units Borosilicate Glass

VITSIL glass distillation units continue to be the most effective, economic method of producing ultra pure water for laboratory use.

VITSIL glass distillation units continue to be the most effective, economic method of producing ultra pure water for laboratory use.By contrast de-ioniser are only effective in removing those substances which are ionized. Further the resins contribute organic impurities to water and an ideal environment for bacterial growth in course of time.

These distillation units are designed to produce a distillate of consistent purity. The unit consists of horizontal borosilicate boilers, condensers and quartz heater. All parts are replaceable.

Innovative Design

The newly developed quartz heater is advantageous than chromium plated heaters used by other manufacturers. Chromium plated heaters react with acids during cleaning process.Quartz heaters do not react with acids or water during cleaning or at elevated temperature unlike metallic ones. Quartz heaters are easy to assemble and dismantle, unlike metallic ones which are bulky.

Advantages

- Compact, simple to use.

- Economical and ideal for colleges and general laboratory use.

- Powder coated stand for rust free operation.

- Provision for easy cleaning of boiler.

Specifications

Single Distillation| MODEL No. | VBSD 1.5L | VBSD 4.0 L |

|---|---|---|

| Dist. Water Output cap. (Approx) |

1.5 lt/hr. | 4 lt/hr |

| Electrical requirements | 230-250 volts single phase 1.5 kw Quartz heater |

230-250 volts single phase 3 kw Quartz heater |

| Cooling water consumption | 50 lt/hr. | 60 lt/hr. |

| Biological Activity | Pyrogen Free |

Pyrogen Free |

| pH | 6 - 7 | 6 - 7 |

| MODEL No. | VBDD 1.5L | VBDD 4.0 L |

| Dist. Water Output cap. (Approx) | 1.5 lt/hr | 4 lt/hr |

| Electrical requirements | 230-250 volts single phase2 x 1.5 kw Quartz heater |

230-250 volts single phase 2 x 3 kw Quartz heater |

| Cooling water consumption | 100 lt/hr. | 150 lt/hr. |

| Biological Activity | Pyrogen Free |

Pyrogen Free |

| pH | 6.9 - 7 | 6.9 - 7 |

For more details, download the brochure

1. Economy Water Stills 1

2. Economy Water Stills 2

Our Products