A supply of pyrogen free distilled water is basic requisite for many research, analytical & industrial laboratories. Moreover, the materials of the distillation apparatus and storage vessels, should be chosen so as to avoid diffusion of contamination into the distillate.

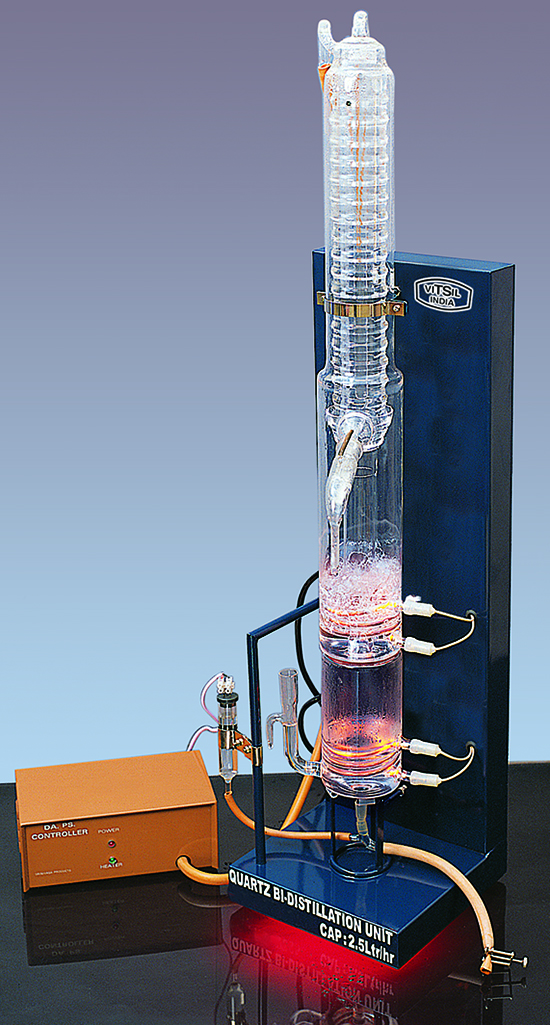

A supply of pyrogen free distilled water is basic requisite for many research, analytical & industrial laboratories. Moreover, the materials of the distillation apparatus and storage vessels, should be chosen so as to avoid diffusion of contamination into the distillate.Quartz distillation units are manufactured from imported fused quartz tubes. The exceptionally high chemical purity and very low solubility of this material enables the production of very high performance system. The greatest possible attention has been taken for technical performance, simplicity of use and efficiency.

Description Of Apparatus

The unit consist of a primary boiler with built-in heater.The primary boiler has a ‘O’ ring groove at the top, on which a silicone ‘O’ ring sits. The secondary boiler with condenser is mounted on the primary boiler.

A double wall condenser ensures separate condensation of vapor coming from the two boilers using a single cooling circuit.

The whole unit is mounted on powder coated stand with electrical terminals for easy connection either to the mains or DAPS (Distillation Apparatus Power Supply) The bottom outlet is connected to a ‘T’ joint of which one limb is connected by a rubber tubing & pinch cock for cleaning sediments in primary boiler by acid wash and other limb to the water leveller of ‘DAPS’.

Demountable Model

In view of calcium & magnesium deposits occurring in primary boiler and the difficulty involved in cleaning these deposits, made us to think of designing the apparatus, so that the primary boiler could be easily dismantled for easy cleaning of calcium & magnesium deposits.Spare bottom boilers are available normally from ready stocks.

Innovative Design

The primary boiler is being provided with a ‘O’ ring which acts as a cushion on which secondary boiler and condenser unit is mounted.Demerits in other brands of distillers

The distillers available in the market provide either glass flange with clamps or glass ball and socket connection. Glass connections are liable for breakages. The calcium & magnesium deposit forms around the ball joint, thereby, freezing the unit. The steam leaking at ball joint is a very common feature in other brands.Silicone rubber boot & fiber glass insulated electrical connections withstand higher temperature and long lasting as compared to rubber boot & PVC insulated wire provided by other manufacturers.

Specifications

| Model No. | VQDD 1L | VQDD 1.5L | VQDD 2.0L | VQDD 2.5L | VQDD 5L |

|---|---|---|---|---|---|

| Dist. Water Output cap. (approx) | 1 lt/hr. | 1.5 lt/hr. | 2 lt/hr. | 2.5 lt/hr. | 5 lt/hr. |

| Electrical requirements | 230 -250 volts single phase 2 kw |

230 -250 volts single phase 3 kw |

230 -250 volts single phase 3.5 kw |

230 -250 volts single phase 4.4 kw |

440 volts 3 phase 8.8 kw |

| Cooling water consumption | 50 lt/hr. | 60 lt/hr. | 65 lt/hr. | 100 lt/hr. | 150 lt/hr. |

| Biological Activity | Pyrogen Free | Pyrogen Free | Pyrogen Free | Pyrogen Free | Pyrogen Free |

| pH | 6.9 - 7 | 6.9 - 7 | 6.9 - 7 | 6.9 - 7 | 6.9 - 7 |

Our Products